- contact@millerandlincolnsuppplys.com

Shopping cart (0)

Subtotal: $0.00

Spend $350.00 to get free shipping

Congratulations! You've got free shipping.

Worldwide Delivery

Ship to over 200 regions and countries.

Secure Payment

Pay with the world most payment methods.

100% Money Back

30 days return policy & guarantee also.

Discount Available

Protect covers payment purchase Gifts.

Miller Trailblazer 330 EFI w/Excel Power, Charger & WIC 907832004

$14,475.00 Original price was: $14,475.00.$11,419.00Current price is: $11,419.00.

20 people are viewing this product right now

Brand:

Miller® Trailblazer® 330 Welder EFI with Excel™ Power, Battery Charger & Wireless Interface Control 907832004

The Miller® Trailblazer® 330 EFI with Excel™ Power, Battery Charger and Wireless Interface Control is a 330 amp DC welder and 12,000 watt AC generator that can also charge and jump start dead batteries, when paired with OPTIONAL #300422 charging cables.

Categories: Welder, Engine Driven Welders

Tag: 907832004

Worldwide Delivery

Ship to over 200 regions and countries.

Secure Payment

Pay with the world most payment methods.

100% Money Back

30 days return policy & guarantee also.

Discount Available

Protect covers payment purchase Gifts.

Miller® Trailblazer® 330 Welder EFI with Excel™ Power, Battery Charger & Wireless Interface Control 907832004

The Miller® Trailblazer® 330 EFI with Excel™ Power, Battery Charger and Wireless Interface Control is a 330 amp DC welder and 12,000 watt AC generator that can also charge and jump start dead batteries, when paired with OPTIONAL #300422 charging cables. Weighing in at just 400 pounds, the Trailblazer 330 is over 80 pounds lighter and 13% smaller than previous Miller Trailblazer models. It is specifically designed to take up less room in your pick up truck or UTV.

The Trailblazer 330’s WIC (Wireless Interface Control) gives you full remote welder control; including remote amp/voltage control and engine start/stop. The wireless interface control is a handheld unit that adjusts all weld parameters, stores custom weld settings, displays real time engine status and service intervals, AND acts as a remote engine start/stop. Wireless interface control saves fuel, reduces jobsite noise, and enhances worker safety and productivity by reducing trips back and forth to the welder. Built-in ArcReach® also allows the Trailblazer 330 to communicate directly with a Miller ArcReach wire feeder or remote control through the welding leads, eliminating the need for costly control cables. Miller’s exclusive AutoSet™ technology allows you to access pre-programmed welding parameters, based on metal thickness and welding process, for easy set up. You can also fine tune your output amperage and voltage manually, to suit your welding style.

The Miller Trailblazer® 330 EFI with Excel™ Power & Battery Charger is the most fuel efficient gas engine welder/generator in its class. It features a Kohler® 23 horse power, fuel injected engine with Miller’s exclusive Auto-Speed™ technology. Auto-Speed matches the engine speed with the welding load. This means that the engine can run at optimum RPM rather than full RPM while under load. This translates into reduced fuel consumption, quieter operation and longer engine life.

Miller’s exclusive Excel™ Power provides 2,400 watts of generator power while the engine is at idle speed, resulting in dramatically reduced fuel costs. Excel Power reduces emissions, operating noise and extends run time hours. The built in battery charger can charge batteries at 12 volts or 24 volts. It produces 150 amps of charging power and up to 300 amps of jump start power.

The Trailblazer® 330 EFI has the most smooth, stable welding arc in the business. It produces X-Ray quality welds whether you are using MIG, Stick or DC TIG welding processes. For MIG welding, the 330 has a direct spool gun connection for Miller Spoolmatic® series and Spoolmate™ 200 spool guns, eliminating the need for a WC-24 weld control. For stick welding, the Trailblazer 330’s Dynamic Dig™ feature produces a consistent arc that is highly adaptive. Lift-Arc™ DC TIG with Quiet Pulse™ is standard on every Trailblazer 330, and produces outstanding results in TIG welding applications time after time.

![]()

Processes (X-Ray Quality)

- Stick (SMAW)

- MIG (GMAW)

- Flux Cored (FCAW)

- DC TIG (GTAW)

- Pulsed DC TIG (GTAW-P)

- Air Carbon Arc (CAC-A) Cutting and Gouging (3/16 in carbons)

- Air Plasma Cutting and Gouging with optional Spectrum models

- AC Generator

Applications

Industrial Applications

Fabrication

Maintenance

Repair

Structural Steel Work

Pipe

Sheet MetalFeatures

![]()

- Wireless Interface Control – With wireless interface control, you can change welding processes, adjust parameters, select and save preset programs, turn the machine on/off, get service reminders and more from wherever you are on the jobsite. Extend time between fill ups and maintenance intervals while eliminating the need to go back to your machine to make adjustments.

300 foot operating range from welder to remote

View engine status, fuel level, and battery charge level of remote.

View and select between all available processes.

Turn contactor on/off manually in remote welding mode. Turn engine on/off with remote.

Save custom presets in up to four programs and easily switch between pre-programmed settings.

Quickly adjust and save arc control settings including DIG, DIG range inductance and Auto-Stop.

Adjust amperage or voltage, by increments or percentage, while welding. - Excel™ Power – Excel power provides 120V, 60Hz of pure sine wave generator power at idle speed and while welding. When connected to the Excel power receptacle, you get up to 2400 watts of the cleanest generator power available. Plus, you can run most jobsite tools – like grinders, chop saws, drills and lights at idle speed, which provides:

Exceptional fuel-efficiency

Extended runtimes

Quieter operation

Longer engine life - EFI gas engine optimizes the air/fuel ratio for all engine speeds and engine loads, resulting in lower operational costs, fewer emissions, longer run times and better performance when compared to carburetor models. The payback from fuel savings alone is a matter of months. EFI will give you:

Easy starts with no choke required

Reliable operation, even with infrequent use – less prone to fuel deterioration

Fuel efficiency – use up to 27 percent less fuel

Fewer emissions – 27 percent less CO and 33 percent lower HC+NOx levels - Battery charge/jump start – Reduce downtime with battery charge/jump start capability. Designed and recommended for mechanics or anyone else responsible for a fleet of trucks or equipment. By using your Trailblazer to charge dead batteries or jump a stubborn engine, you ll keep your crew working and the fleet up and running.

Note: Battery charge/jump cables (300422) must be ordered separately.

- ArcReach® standard on all models – ArcReach® technology uses the existing weld cable to communicate welding control information between a Miller® ArcReach® feeder or ArcReach® Stick/TIG remote and Bobcat® 265.

- This technology eliminates the need for control cords, and their associated problems and costs.

- Designed for the professional welder – The Trailblazer® 330 delivers unbeatable arc performance in all weld processes, providing the smoothest, most stable arc in the industry.

![]()

- Ultra-adaptive arc control – Unlike conventional DIG that provides a preset amount of short-clearing current, Miller-exclusive Dynamic DIG technology works on a time-based algorithm that automatically adjusts the amount of current required to clear a short. Delivers a smoother more consistent arc that can be tailored to match application, material, fit-up and welder technique.

![]()

- Lift-Arc™ DC TIG with Quite Pulse™ – DC TIG arc is initiated without the use of high frequency. Simply touch the tungsten electrode to the work piece and lift. Quiet Pulse pulsed TIG welding gives you superior control of the welding arc while eliminating the noise typically associated with pulsed TIG welding processes.

- Direct spool gun connection – Connect a Miller Spoolmatic® Series or Spoolmate™ 200 spool gun directly to the welder. No need for a WC-24 weld control.

- Smart-Cor™ technology – Independent weld and generator power in an improved, more compact design.

No interaction between jobsite tools and the welding arc, resulting in:

Stronger, cleaner, more efficient generator power

Reduced size and weight

Improved arc performance

- Auto-Speed™ technology – Automatically adjusts the engine speed to run at lower speeds depending on the total power needed, resulting in:

Exceptional fuel-efficiency

Extended run times

Quieter operation

Reduced emissions - Innovative design – Engine is rotated to the front to create more efficient airflow, resulting in:

Quieter operation

Reduced size and weight

Easier maintenance - More portable, uses less truck space – Miller Trailblazer 330 welder/generators are up to 13% smaller and 80 lbs. lighter than previous models, which means moving them is faster and easier, for maximum productivity. And because they take up less space, Trailblazer welder/generators let work trucks carry more equipment and gear, so your work crews can be ready for anything.

![]()

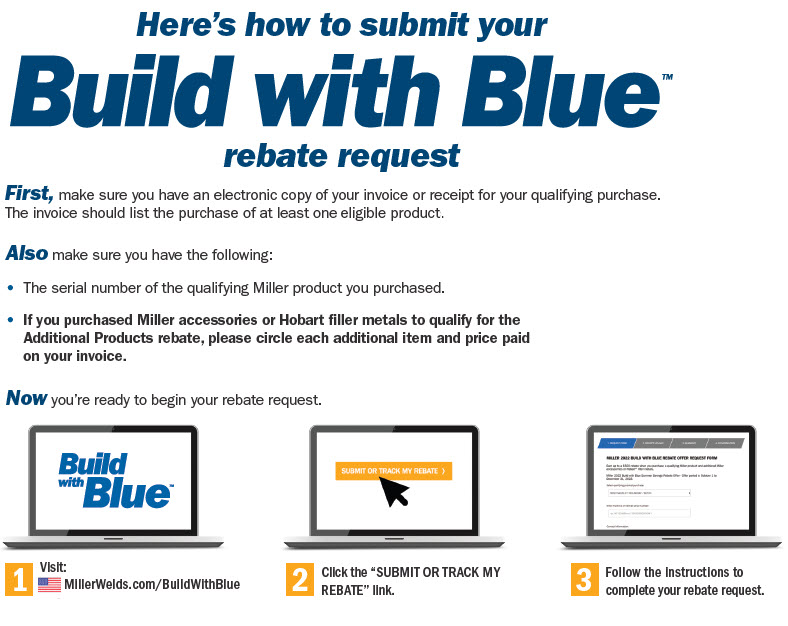

Earn additional rebates when you purchase additional Miller® branded accessories or Hobart® filler metals.

Be the first to review “Miller Trailblazer 330 EFI w/Excel Power, Charger & WIC 907832004” Cancel reply

Payment security

Encryption ensures increased transaction security. SSL technology protects data linked to personal and payment info.

More

More

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.