- contact@millerandlincolnsuppplys.com

Shopping cart (0)

Subtotal: $0.00

Spend $350.00 to get free shipping

Congratulations! You've got free shipping.

Worldwide Delivery

Ship to over 200 regions and countries.

Secure Payment

Pay with the world most payment methods.

100% Money Back

30 days return policy & guarantee also.

Discount Available

Protect covers payment purchase Gifts.

Miller Deltaweld 500 MIGRunner w/Intellx Elite Dual Feeder 951955001

$24,350.00 Original price was: $24,350.00.$21,084.00Current price is: $21,084.00.

9 people are viewing this product right now

Brand:

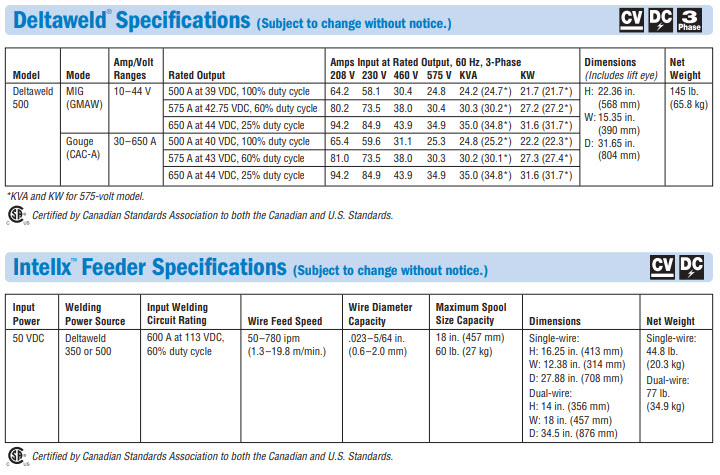

Miller® Deltaweld® 500 MIGRunner with Intellx™ Elite Dual Feeder 951955001

The Miller® Deltaweld® 500 MIGRunner with Inellx™ Elite Dual Feeder is a complete 650 amp MIG welding system that comes standard with pulsed MIG capabilities and expanded welding programs.

Categories: Welder, Mig Welders

Tag: 951955001

Worldwide Delivery

Ship to over 200 regions and countries.

Secure Payment

Pay with the world most payment methods.

100% Money Back

30 days return policy & guarantee also.

Discount Available

Protect covers payment purchase Gifts.

Miller® Deltaweld® 500 MIGRunner with Intellx™ Elite Dual Feeder 951955001

The Miller® Deltaweld® 500 MIGRunner with Inellx™ Elite Dual Feeder is a complete 650 amp MIG welding system that comes standard with pulsed MIG capabilities and expanded welding programs. The advanced technology of both the Deltaweld 500 welder and the Intellx Elite feeder means that professional, superior quality welds are consistently produced regardless of the skill level of the operator. With a 28% wider operating window and more forgiving arc, the Deltaweld 500 increases productivity by reducing weld clean up and training time.

The Intellx Elite wire feeder comes complete with full color LCD screen, soft keys and memory buttons, plus advanced features like EZ-Set MIG, EZ-Set Accu-Pulse™, expanded pre-programmed parameters for advanced MIG welding, plus two trigger receptacles – one for standard MIG guns, and one for an OPTIONAL XR-Aluma-Pro™ Plus push-pull gun.

Complete MIGRunner package includes Deltaweld 500 welder, Intellx Elite wire feeder, feeder mount with swivel base, two Bernard™ BTB 400 amp MIG guns, running gear with dual cylinder rack, flowmeter/regulators and all interconnecting cables and gas hose.

![]()

Processes

- MIG (GMAW)

- Pulse MIG (GMAW-P)

- Accu-Pulse® MIG (GMAW-P)

- Flux Cored (FCAW)

- Carbon Arc Gouging (CAC-A)

Applications

Heavy Industrial Manufacturing

General manufacturing

General fabrication

Structural steel fabrication

Transportation

Sheet metal fabrication

Light-gauge tube and sheet

Features

- Intellx™ Elite Dual Feeder – arc control feature means welders can produce better welds with minimal parameter adjustment. Comes standard with full color LCD screen, Accu-Pulse®, EZ-Set, steel weld programs, expanded weld programs, memory buttons and MIG gun and push-pull gun trigger receptacles.

- Dual-wire model allows two different wire types to be available on one feeder, avoiding downtime from changing spools and drive rolls.

- Legacy meets pulse – Accu-Pulse® offers a more forgiving arc and compensates for variations in operator technique, providing a wider operating window.

- Easy to use – EZ-Set simplifies parameter setup based on material thickness, removing complexity.

- Quality-engineered cable management – protects your connections to keep you productive.

- Wind Tunnel Technology™ – Internal air flow that protects electrical components and PC boards from dirt, dust, debris – greatly improving reliability.

- Fan-On-Demand™ – operates only when needed reducing noise, power consumption, and the amount of airborne contaminants pulled through the machine.

- ArcConnect™ – is a next generation communication that utilizes high speed signals to improve weld performance and allow point-of-use controls to be located at the feeder.

- Gouge Mode- Deltaweld 500 has a dedicated constant current carbon arc gouge mode specifically designed to gouge up to 3/8″ carbons.

- Intellx Elite available welding programs include:

Steel

Stainless steel

Flux-cored

Metal-cored

Aluminum

Different wire sizes

Different gas types

Comes complete with

- Deltaweld® 500 MIG welder with ArcConnect™

- Intellx™ Elite Wire Feeder

- 2 Bernard™ BTB 400 amp MIG guns

- 2 .035/.045 in. V-groove drive rolls

- 2 Flowmeter/Regulators

- Deltaweld® 500 running gear/cylinder rack

- Feeder swivel kit

- Cart accessory kit

- ArcConnect™ control/motor cable 9ft.

- FREE Miller® T94i™-R PAPR (Powered Air Purifying Respirator

Be the first to review “Miller Deltaweld 500 MIGRunner w/Intellx Elite Dual Feeder 951955001” Cancel reply

Payment security

Encryption ensures increased transaction security. SSL technology protects data linked to personal and payment info.

More

More

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.