- contact@millerandlincolnsuppplys.com

Shopping cart (0)

Subtotal: $0.00

Spend $350.00 to get free shipping

Congratulations! You've got free shipping.

Worldwide Delivery

Ship to over 200 regions and countries.

Secure Payment

Pay with the world most payment methods.

100% Money Back

30 days return policy & guarantee also.

Discount Available

Protect covers payment purchase Gifts.

Lincoln Flextec 350X PowerConnect Welder (Tweco) K4273-1

$8,352.00 Original price was: $8,352.00.$6,533.00Current price is: $6,533.00.

49 people are viewing this product right now

Brand:

Lincoln® Flextec® 350X PowerConnect® Multi-Process Welder (Tweco®) K4273-1

The Lincoln® Flextec® 350X PowerConnect® K4273-1 is a 350 amp multi-process welder that operates on 200-575 volt, single or three-phase input power.

Categories: Multi-Process Welders, Welder

Tag: K4273-1

Worldwide Delivery

Ship to over 200 regions and countries.

Secure Payment

Pay with the world most payment methods.

100% Money Back

30 days return policy & guarantee also.

Discount Available

Protect covers payment purchase Gifts.

Lincoln® Flextec® 350X PowerConnect® Multi-Process Welder (Tweco®) K4273-1

The Lincoln® Flextec® 350X PowerConnect® K4273-1 is a 350 amp multi-process welder that operates on 200-575 volt, single or three-phase input power. The PowerConnect feature allows the welder to automatically detect any input power type – regardless of voltage or phase. It then optimizes the 350X to run on the supplied input electricity without any manual linking or switching. The Flextec 350X PowerConnect is capable of MIG, Pulsed-MIG, Flux-cored, DC TIG and Stick welding.

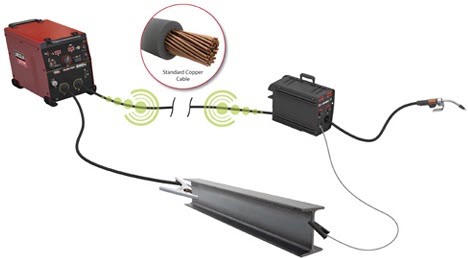

The 350X PowerConnect also comes with CrossLinc®. Built-in CrossLinc® technology means that the Flextec 350X communicates with an OPTIONAL CrossLinc remote or Lincoln X Series voltage-sensing wire feeder directly through your welding leads. Full remote amperage and voltage control is achieved without the use of a separate remote-control cable. Standard voltage sensing wire feeders may also be used, but CrossLinc remote control functionality will be disabled. The 350X PowerConnect can also be used will virtually all types of Lincoln wire feeders, including Lincoln ArcLink® digital feeders.

The Flextec 350X PowerConnect is built to be a rugged performer on the harshest job sites. It is rated IP23 for welding in outdoor weather conditions. The 350X also comes with Lincoln’s Desert Duty® certification, meaning it can keep welding in temperatures up to 131 degrees F. Heavy duty alloy carrying handles, powder-coated aluminum case and shock absorbing rubber feet make this an impact resistant power source that will stand up to abuse.

The Flextec 350X PowerConnect operates on virtually any electrical power in the world, 200-575 volt, single or three-phase. It comes with Tweco®-style cable receptacles and Lincoln’s three-year warranty.

Processes

- MIG (GMAW)

- Pulsed MIG (GMAW-P

- Flux-Cored (FCAW)

- DC TIG (GTAW)

- Stick (SMAW)

- Air-Carbon Arc Gouging (CAC-A)

Applications

Fabrication

Construction

Shipbuilding

Structural

Pipe

Features

- Tweco®-Style Cable Receptables

- PowerConnect® Technology

Automatically connects to any input power from 200-600 volts, single or three phase.

Allows the machine to be used anywhere in the world and compensates for large fluctuations in incoming voltage.

- CrossLinc® with True Voltage Technology™

CrossLinc® allows for amperage and voltage control at the welding arc to improve control of your operation.

No need for an additional control cable communication occurs directly over the weld cables.

True Voltage Technology™ compensates for voltage drop across the welding circuit.

TVT™ will measure the voltage drop and adjust the power source to compensate for the difference between the desired voltage and actual voltage at the weld.

- Multi-Process Power Source for all Your Welding Needs

Optimized stick welding for both cellulosic and low hydrogen electrodes.

Touch-Start TIG® for reducing contamination during starts without high frequency.

Compatible with ArcLink® digital feeders, CrossLinc® and 42V analog, and GMAW and FCAW.

Performs STT™ (Surface Tension Transfer) when paired with a Lincoln Activ8X™ pipe wire feeder.

Performs pulsed-MIG welding when paired with an Lincoln ArcLink® digital wire feeder

- Field Proven Ruggedness and Durability

Engineered for outdoor use and harsh environments.

IP23 rated for use in outdoor weather conditions.

Desert Duty rated for operation at temperatures up to 55° C (131° F).

Trayed and potted PC boards to help withstand welding dust and humidity.

Smart fans run at variable speeds to keep internal machine components cool.

Tough alloy handles for lifting and impact protection.

Lightweight aluminum powder painted case for rust protection.

Shock Absorbing Rubber Feet for impact protection

PLEASE NOTE: This is a DC TIG welder ONLY. It CANNOT TIG weld aluminum.

Comes complete with

- Flextec® 350X PowerConnect® Multi-Process Welder with Tweco®-style receptacles

- 8.5ft 4 conductor/ 8 AWG input power cable

Be the first to review “Lincoln Flextec 350X PowerConnect Welder (Tweco) K4273-1” Cancel reply

Payment security

Encryption ensures increased transaction security. SSL technology protects data linked to personal and payment info.

More

More

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.